2. Historical Information

3. Hardware

3.3. Lisa Hardware Introduction

3.4. Chassis

3.5. Expansion Slots

3.5.1. Lisa Office System and Expansion Slots

3.5.2. Dual Parallel Card

3.5.3. Quad Serial Card

3.5.4. SCSI Interfaces and Devices

3.6. Floppy Drives

3.7. Hard Drives

3.7.2. Hard Drive Problems

3.7.3. ProFile External Hard Drives

3.7.4. Widget Internal Hard Drives

3.8. The Lisa I/O Board

3.8.4. COP421 Control Oriented Processor

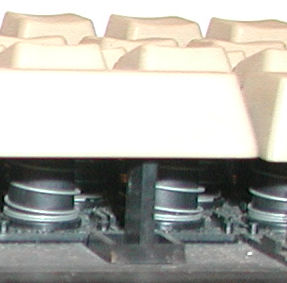

3.9. Keyboard

3.10. Floppy, Twiggy, and Tape media used with the Lisa

3.10.1. Floppy Media

3.10.2. Twiggy (FileWare) Media

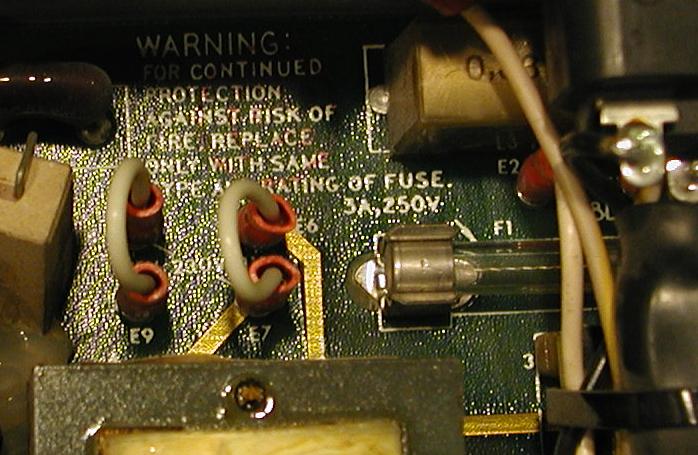

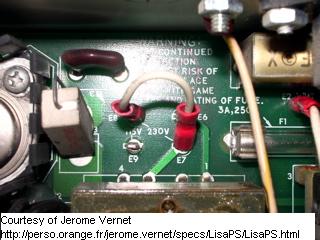

3.11. Power Supply and Power issues

3.12. Printers

3.13. Serial Ports

3.14. Lisa ROMs

3.15. Memory

3.16. Video and CRT

4. Lisa Software

4.4. Lisa Office System

4.4.7. Lisa Office System HowTo's

4.5. Lisa Workshop

4.6. MacWorks

4.6.3. MacWorks XL

4.6.4. MacWorks Plus

4.6.5. MacWorks Plus II

4.7. Microsoft/SCO Xenix

The Answers:

1.1. About this FAQ

This FAQ attempts to gather knowledge about the Apple Lisa computer in a central place, whether technical or historical.The goal is to provide information that helps preserve existing Apple Lisa computers, aids in their repair, as well as provides historical and educational information about this historically significant machine.

Lisa used to be a trademark of Apple, Inc. Since I'm not a lawyer, I don't know the current status of this trademark, and ask that if Apple still holds this trademark, that you optionally visualize a trademark symbol following every instance of the word Lisa, Apple, Apple ]&Macintosh, iPod, PowerBook, MacBook Pro, ad vomitus, ditto for other registered or non-registered trademarks. Information in this FAQ was gathered from a variety of sources, including but not limited to, web searches for the words "Apple Lisa", the LisaList, David T. Craig's Lisa archives, various articles, books, the Sun Remarketing Lisa and Mac XL Do it Yourself Guide , personal knowledge and experience, and other materials that I've forgotten. Some of the documents were quoted verbatim, others paraphrased, so that they would better fit the FAQ format. In every instance, except for the knowledge in the backs of our minds, credit to the source was given. This FAQ is not connected with, nor sponsored by any commercial entities. Any mention of products, stores, websites, etc. is purely for informational use, because I've heard about it, or have used it. There are no commercial interests in anything listed herein. (i.e. the page listing 3.5" floppies.) If you find anything you'd like to add, or have corrections, suggestions, flames, or spam, please send them by email to mailto:lisafaq@sunder.net. Information in this FAQ is believed to be accurate, but might not be. Links to websites outside of this domain such as those to online stores (for example, the page listing 3.5" floppies) may vanish without notice or reason. Some of the repairs and procedures listed here are inherently dangerous as they involve work with high voltage components. Proceede with caution, and apply all possible precautions, but note that you do so at your own risk whether your have read this disclaimer or not. (Whatever happened to being responsible for your own actions? i.e. not jumping off a cliff because you saw it on Simpsons episode?) Donations of Lisa hardware (or other historical computer equipment), modern computers (AMD64, UltraSparc IV, MacBook Pro's or Powerbooks preferred), ipods, software, books, or good ol'e hard cash are very gladly accepted.

Information in this FAQ was gathered from a variety of sources, including but not limited to, web searches for the words "Apple Lisa", the

�(Comment on this answer)

2.1. What is the Apple Lisa?

The Apple Lisa is a computer built by Apple Computer, Inc. between 1979 and 1983. It is one of the first commercial machines to have a graphical user interface, use a mouse, and have an interface that contained icons, windows, pull down menus, dialog boxes.

About the Lisa's design

Although the Lisa is considered a microcomputer, it was designed by ex-minicomputer designers, and has minicomputer features. For exampled, it contains two CPU's (a Motorola 68000 and a 6504), and a COP421 microcontroller. The main processor is the 32 bit MC68000. The 6504 is used as a dedicated controller for the floppy drives. The COP421 microcontroller is used for the system clock, power management, keyboard and mouse interface.

The Lisa was designed to be a personal computer. This was a huge departure from both from the shared mainframe with multiple terminals model, as well as character, or text based, personal microcomputers computers. Unlike most mini or mainframe machines of the era, the Lisa provided multi-tasking for one user, rather than time sharing for many users.

The hardware design is clean, and contained features from high end micros. For example, it supports virtual memory (via a memory management unit that provides for both application multitasking as well as preventing one application from crashing another), hard drives, a serial communications controller that can talk to mainframes over SDLC, and so on.

The design of the case makes it easy for the end user to service the Lisa. Almost every card/device is user replaceable.

Various operating systems were developed for the Lisa hardware. Of these, the Lisa Office System has had the most influence and impact, and so deserves much of the credit for the significance of the Lisa.

About the Lisa Office System

The Lisa Office System is a very sophisticated OS that at its core has a lot of similarities to Unix (multitasking, virtual memory, MMU, named pipes as files, device control as files.)

On top of this the user is presented with a highly polished graphical user interface that uses a document oriented metaphor instead of the application oriented model of other computers. For example, you don't run LisaWrite to compose a memo. Instead, you tear off a sheet of stationary to compose your memo. You could then open a LisaCalc spreadsheet and copy and paste data into the memo from the spreadsheet. This is done through a mechanism similar to OpenDOC, or OLE (renamed to ActiveX.)

Documents, and filenames

Users don't have to use the "save" command in a File menu on documents unless they want to ensure that recent changes have been written to the disk, or want to immediately save and put away the file (which closes it).

There also is no File Open or File Save dialog box, which to this day plagues every modern GUI out there with a miniature finder/explorer that doesn't quite have the same functionality as the real thing, and causes frustration. This completed the illusion that icons expanded themselves to documents, or better said, that icons are documents. The Lisa had it right

Multiple documents can have the same file name. If you duplicate a LisaWrite document, you get two copies, both with the same name, without having a conflict! This is because the desktop names on the Lisa are virtual. Underneath the pretty GUI, the file system names things uniquely. Think of it this way, when a user makes a copy of a document for another using a photocopier, there are now two identical copies. The user doesn't have to explicitly rename one of them, or worry about document names.

The user never sees any of the underlying operating system files, so they can't harm the operating system by deleting its files.

Backups?

The Lisa Desktop is able to split a file that is greater than a 400K floppy across multiple floppies. When you attempt to copy it back to the hard drive, it asks you to insert the next floppy and says/The Lisa is reconstructing "filename" on "hard disk"./ You can back up your hard drive by simply dragging it to an empty floppy, and the Desktop Manager will ask you for another disk, and then another, until you have made a full backup.

Users don't need to launch a separate program to do backups.

Other Innovations

The Lisa also has features such as a built in screen saver that after a few minutes of inactivity will dim the screen to a user specified brightness.

Unlike most personal computers that have a big red switch to control power, the Lisa uses a software managed power supply. When the user presses the power switch, it acts as a special keystroke; instead of just powering off, the Lisa Office System puts all the files "away" (saving the changes), and then, once it is safe to do so, it tells the COP421 controller to power the Lisa off.

On the next power up, the Lisa will open all the windows and opened documents to the exact position where the user left off

This is similar to hibernating, sleeping, or standby on modern computers. Yet, all of this is done without swapping all of the Lisa's memory to disk, or keeping the main CPU in a low power state to preserve the contents of memory!

Instead, every Tool (Lisa Application) remembered where the user left off and resumes to the same position the next time the Lisa is powered. Compared to "modern" software packages, where it's up to the programmer to provide some option to save state, but requires the user to explicitly do so the next time that application is launched.

Summary

Many of the features of the Lisa hardware and Lisa Office System were lost as Apple switched to the Macintosh instead. Some, over time made their way back in, others showed up in various other operating systems, but none have the same look and feel as the Lisa, nor the same tight integration between applications, documents, operating system, and hardware. The only other machine with this high level of integration would be Apple's Newton.

(No, before you ask, in Lisa Office System, one does not drag the floppy to the trash can to eject it)

Lisa is a much nicer equivalent of a modern day office suite (with memory/storage/CPU limitations) but existed over 20 years ago.

These are the features that make this a great, and very unique machine, which was truly ahead of it's time.

Sadly, Lisa was replaced by a machine that was its mere shadow. The original Mac 128 was considered crippled when compared to the Lisa. With only 128K of RAM, it could only run one program at a time. To do any real work, an external floppy drive was required. The alternative was a horrible incessant swapping of floppies every few seconds.

Fortunately, the Mac has evolved over time, and while it lacks the same level of integration as the Lisa did 25 years ago, it has matured quite nicely.

�(Comment on this answer)

2.2. What books mention, or are about the Lisa?

There are quite a few books that have information about the Apple Lisa. There are some that are technical, and some about Apple, Inc., which contain mentions, or historical information about the Lisa. There's even a movie

Technical Lisa Books

- Apple Lisa: A User-Friendly handbook by Joseph Coleman Amazon

- Apple Lisa User's Handbook by Inc. Weber Systems Amazon

- The Complete Book of Lisa by Kurt J. Schmucker Amazon

- Macintosh Hardware Repair Secrets by Larry Pina Amazon

- The Apple Lisa Handbook by Michael J. Posner A Collection of quotes and clippings about the Lisa

Books of Historical Interest about the Lisa

- Mac Bathroom Reader by Owen W. Linzmayer much of the same information. Amazon

- Revolution in the Valley by Andy Hertzfeld, et al. Amazon whose text can also be found here: http://folklore.org

- West of Eden: The End of Innocence at Apple Computer by Frank Rose Amazon

- The Little Kingdom: The Private Story of Apple by Michael Moritz Amazon

There's even a movie

- The Pirates of Silicon Valley (Movie on DVD) movie website Amazon

�

(Comment on this answer)

2.3. What Lisa Websites are out there?

Apple Lisa Mailing List

- http://lowendmac.com/lists/lisa.html Lisa List - (defunct)

- https://lisalist2.com Lisa List2 - Replacement for the above.

The Apple Lisa Emulator and related

- http://lisaem.sunder.net LisaEm is the world's first fully functional Lisa emulator.

- http://lowendmac.com/hodges/07/0313.html Interview with Ray Arachelian, Creator of the Lisa Emulator, Ted Hodges, LEM

- http://slashdot.jp/interview/article.pl?sid=07/04/02/011220 Japanese translation of the above

- http://lowendmac.com/hodges/07/0227.html Lisa Emulator Released, Allows OS X and Windows Users to Experience Apple's Lisa, Ted Hodges, LEM

- http://slashdot.jp/mac/article.pl?sid=07/04/02/0132202 Japanese translation of the above.

- http://www.mactime.ru/Environ/WebObjects/mactime.woa/2/wa/Main?textid=6961&level1=mactimes&wosid=rrSRvMJJdYd7CdcLebqqKw Russian translation of the above?

- http://retromaccast.libsyn.com/index.php?post_id=196147 James and John interview Ray Arachelian at the Retro Mac Cast (m4a)

Unique, Fun Pages

- http://www.lisa2.com/ A Lisa being used as a webserver

- http://myoldmac.net/SELL/CompuBots.htm CompuBots - original Lisa artwork

- http://www.kreativekorp.com/kko/pixel/fonts.html Lisa Fonts for your Mac (scroll down about half way.)

- http://www.masswerk.at/schemes.htm Kaleidoscope Themes - including a Lisa one

- http://www.jg.org/folk/artists/fredsmall/applelisa.html The Heart of the Apple Lisa - song

Papers and Articles

- http://lowendmac.com/hodges/07/0402.html Using Apple's Lisa for Real Work - Ted Hodges, LEM

- http://retrobits.libsyn.com/index.php?post_id=175947 The Apple Lisa - podcast at RetroBits

- http://lisa.sunder.net/mirrors/Simon/Lisa/LisaLegacy/LegacyIndex.html The Legacy of the Apple Lisa Personal Computer: An Outsider's View, by David T. Craig

- http://members.safe-t.net/jwalker/programming/lisaLegacy/ The Legacy of the Apple Lisa Personal Computer: An Outsider's View, by David T. Craig (mirror)

- http://lowendmac.com/tech/lisa.html "The Innovative Lisa"

- http://www.guidebookgallery.org/articles/thelisacomputersystem "The Lisa Computer System" Byte Magazine Feb 1983

- http://lowendmac.com/musings/03/0120.html "Lisa's Legacy" on the Lisa's 20th Anniversary

- http://lowendmac.com/orchard/05/1005.html "A History of Apple's Lisa 1979-1986"

- http://www.pegasus3d.com/apple_screens.html Designing Lisa UI

- http://www.semaphorecorp.com/ss/toc.html Semaphore Signal - a Magazine for Lisa users

- http://web.archive.org/web/20040328125354/http://www.cs.berkeley.edu/~jasonh/cs39i-seminar/p40-perkins.pdfInventing the Apple Lisa Interface

- http://www.mprove.de/diplom/text/3.1.8_lisa.html Apple Lisa in Vision and Reality of Hypertext and Graphical User Interfaces

- http://en.wikipedia.org/wiki/Apple_Lisa WikiPedia entry for Apple Lisa

- http://folklore.org Folklore.org

- http://folklore.org/StoryView.py?project=Macintosh&story=Busy_Being_Born.txt Busy Being Born - Building the Lisa UI

- http://www.cyberlaw.com/cylw994.html Apple Loses Lawsuit

- http://lowendmac.com/orchard/05/1005.html A History of Apple's Lisa, 1979-1986

- http://www.mprove.de/diplom/text/3.1.8_lisa.html The Lisa part of Matthias Mueller-Prove's Master Thesis: Vision and Reality of Hypertext and Graphical User Interfaces

- http://www.cs.utc.edu/jdumas/cs460/papersfa02/applelisa/index.htm Apple Lisa Architecture - A Paper by Jon Freeland, Joslin Hendricks, Keith Powell, Sharad Tiwari from the University of Tennessee CS460 Fall 2005

- http://inventors.about.com/library/weekly/aa043099.htm Inventors of the Modern Computer - The History of the Graphical User Interface or GUI - The Apple Lisa (some incorrect specs though)

- Http://www.jagshouse.com/lisa2.html Whatever happened to the Lisa? Article by John C. Dvorak. at Jaghouse

- http://www.vcnet.com/bms/departments/innovation.html Microsoft Hall of Innovation Article mentions things borrowed from the Lisa

- http://www.mackido.com/Innovation/index.html MacKido Contributions Article Mentions who contributed what for Mac/Apple

- http://www.mackido.com/Interface/ui_history.html Microsoft, Apple and Xerox - The History of the Graphical User Interface

- http://www.usfca.edu/usf/turner/interface-history.html An Unofficial History of Advances in Computer Interfaces

- http://www.cs.cmu.edu/~amulet/papers/uihistory.tr.html A Brief History of Human Computer Interaction Technology

- http://news.com.com/2009-1041_3-6053877.html Apple's 30th Anniversary - Designing the Lisa and Mac UI's

- http://www.byte.com/art/9509/sec7/art24.htm Byte: 20 Spectacular Failures - One Paragraph on the Lisa

Photos

- http://tom.stepleton.com/catalog.php?show=2002-12-01 Beauty photos of Lisa

- http://www.macgeek.org/museum/applelisa1/ Pictures of an Apple Lisa 1

- http://www.guidebookgallery.org/extras/spotlights/lisa GUIde Book Gallery - see what the Lisa's UI looked like

- http://www.digibarn.com/collections/systems/apple-lisa1/index.html Apple Lisa 1 Pictures at DigiBarn

- http://www.digibarn.com/collections/systems/apple-lisa2xl/index.html Apple Lisa 2 and XL pictures at DigiBarn

Video

- http://www.digibarn.com/collections/movies/digibarn-tv/gui-movies/apple/ Apple GUI movies

- http://www.guidebookgallery.org/videos/lisatvad Apple Commercial featuring the Lisa and Kevin Costner

- http://www.esm.psu.edu/Faculty/Gray/graphics/movies/apple_lisa_kevin_costner_1983.mov another copy of the same

Museums, spec sheets, etc.

- http://www.binarydinosaurs.co.uk/Museum/Apple/lisa/index.php Lisa page at Binary Dinosaurs

- http://www.dgatx.com/computing/people/Apple/hs.html Timeline of Apple history

- http://www.old-computers.com/museum/computer.asp?c=265&st=1 Old Computers Lisa Page

- http://applemuseum.bott.org/ Apple Museum

- http://lowendmac.com/orchard/05/1005.html A History of Apple's Lisa, 1979-1986

- http://www.vintagemacmuseum.com/vmm-extras.html The Vintage Mac Museum

- http://fp3.antelecom.net/gcifu/applemuseum/ Greg Cifu's Apple Museum

- http://www.geocities.com/SiliconValley/Lakes/6757/LISA2.HTML Timeline and history

- http://www.fortunecity.com/marina/reach/435/lisa.htm Another Lisa history page

- http://www.lowendmac.com/lisa/index.shtml Low End Mac - Lisa Page

- http://www.macmothership.com/ Huge collection of Lisa advertising brochures, pictures, etc.

- http://www.apple-history.com/lisa.html Apple History on the Lisa

- http://apple2history.org/museum/computers_lisa/lisadesktop.html Lisa Desktop and Pix

- http://www.applefritter.com/node/3191 Lisa page at AppleFritter

- http://ruby.he.net/~sigma/xlisa.html X/Lisa Page

- http://www.brouhaha.com/~eric/retrocomputing/lisa/twiggy.html Good info on the Lisa's Twiggies

- http://www.sunrem.com/ Sun Remarketing

Lisa documentation and software

- http://vintage.tsfsc.com/the-archive/Apple%20Lisa/ Huge Lisa Archive (not all disk images work)

- http://www.1000bit.net/support/manuali/manuali.asp David Craig's docs.

- http://lisa.sunder.net/books.html Lisa manuals and books (in page by page gif or jpg format)

- http://www.whoopis.com/lisa/ "Raoul's Lisa/MacXL Tech Info and Software"

- http://www.macmothership.com/lisacontent/lisahome.html Lisa System and application Software

- ftp://wac.callapple.org/pub/66.223.113.50/pub/Lisa An extensive archive of Lisa Software

- http://pastis.dyndns.org/LisaSoftware/ lisa software

Old Web Pages Mirrored

- http://lisa.sunder.net/mirrors/Simon/Lisa/Index.html Mirror of simon@atomicnet.com.au Circa Jan 1999

- http://lisa.sunder.net/mirrors/desieh/HISTORY.HTM Partial Mirror of Desie Hay's (desieh@southcom.com.au) Site Circa Nov 1998

- http://web.archive.org/web/19980212221412/galena.tjs.org/~tom/ Tom Stepleton's Web page (Internet Archive)

Search engine indexes

- http://dmoz.org/Computers/Systems/Apple/Lisa/

- http://images.google.com/images?q=apple+lisa&hl=en Google Images of Lisa

- http://search.ask.com/web?q=apple+lisa&qsrc=0&o=0 Teoma/Ask.com Lisa search

Replacement Lisa Hardware

- http://sigmasevensystems.com/xprofile The X/ProFile is a commercial replacement for the Lisa and Apple II or ///'s.

- http://john.ccac.rwth-aachen.de:8000/patrick/idefile.htm IDE-File is a non-comercial DYI project.

- http://tinyurl.com/2hw3vd eBay Search for Lisa (had to use tiny url as the target url is monstrous.)

(Comment on this answer)

3.1. My Lisa doesn't work. What general things can I check or do?

If the Lisa seems to turn on, but you don't see anything on the screen, the brightness may be set too low. Try adjusting the display controls (on the rear above the power cord).There are safety interlock switches that are engaged by the front and back covers. If these covers are not properly seated, the Lisa will not turn-on.

The front panel interlock switch is at the lower left. The rear panel interlock switch is near the top of the power supply.

For the most part, the interlock switches are for the safety of the Lisa, as it is difficult to reach dangerous voltages with only the front and back removed. The interlock switches can by defeated using folded cardboard or some other non-metallic item to depress the switch while the cover is removed. Use due care and proceed at your own risk if you operate your Lisa with any covers removed.

A used Lisa may not turn on because it is missing some component. In order to turn on, a Lisa requires:

- power supply

- card cage with motherboard

- I/O board

In order to show something on the screen, a Lisa also requires:

- CPU board

- one or two memory boards

- CRT, video card, and flyback transformer (the latter two are hidden in the chassis behind the CRT)

It is common for a Lisa to not power up or work properly due to poor contacts, below is a procedure for cleaning the contacts:

When handling Lisa components, take care to prevent damage due to ESD (electrostatic discharge).

Take out the Power Supply and card cage, and remove the CPU, I/O, and memory boards, as well as any expansion slot cards. Examine both sides of the card-edge connectors of each. Clean them with electronic contact cleaner or alcohol, and for extreme cases, a pencil eraser (be very gentle or the gold plating will be erased). Make sure that there's no oxidation left (or rubber from the eraser). Examine and if necessary, clean the card-edge receptacles.

Unplug any floppy/twiggy drives and any hard drives. Check their connectors are straight and clean.

Reseat the cards and make sure that they make contact properly. Some cards develop a warp and may not make contact all along the card edge.

Try to power the Lisa on with just the I/O board plugged in.

If that works, shut the Lisa off (you may have to pull out the power cord), and insert the CPU board without memory. This should cause the Lisa to beep and perhaps show an alternating video pattern (since there is no memory for the display.)

If this works, power the Lisa off again, insert a single memory board in the first slot. Power the Lisa on. If it doesn't work, swap it with another memory board. If it doesn't work, try the other slot. If it still doesn't work, you may have a bad memory board (or a bad CPU board.)

�(Comment on this answer)

3.2. What hardware upgrades exist for the Lisa?

Apple products

- Dual Parallel Port Expansion Card

- 512KB Memory Card (most Lisas have both slots filled as only MacWorks XL would work with 512K)

- 5 MB ProFile Hard Disk

- 10 MB ProFile Hard Disk

- Square-pixel screen modification kit (for use with MacWorks XL, MacWorks Plus, and MacWorks Plus II)

- 1.8 Amp "DataPower" Power Supply (Standard in Lisa 2/10, recommended for all Lisa computers)

- For a brief time, Apple offered an exchange program; for trading in a Lisa 2/5 or 2/10, you received a Macintosh Plus and HD20.

Third Party Products

AST

- RamStak memory board (configurable as 512K, 1M, 1.5M, or 2M)

Tecmar

- Four Port Serial Card (for use with Xenix only)

Sun Remarketing

- Double Sided 3.5" 800K Floppy Drive

- SCSI card (for use with MacWorks Plus and MacWorks Plus II)

- SIMM Memory Card (512K, 1M, 1.5M or 2M total)

- Sun20, 30, 40 Hard Drive (20-40MB Parallel Port hard drive installed internally above the floppy drive)

Neville and Steel

- LisaDAC Sound Card (rare) - provides sound capability similar to Mac Plus

Query Engineering Inc.

- Name changed to Sigma Seven Systems Ltd. in 1993 - see below

Sigma Seven Systems Ltd.

- XLerator - 16 MHz 68000 with 4 SIMM sockets, optional SCSI port, optional MC68881/2 FPU for use with MacWorks XL, MacWorks Plus, and MacWorks Plus II

- optional modification for the above supports 4MB SIMMs

- X/Lisa SCSI Accessory Card - provides 50 pin SCSI connector for XLerator SCSI port, and facility to boot SCSI drive from the "Startup From" menu

- XLerator 12.5 - 12.5 MHz 68000 with 2 SIMM sockets

- XLerator 18 - 18 MHz 68000 with 2 SIMM sockets

- QuickBoot - Upgrade ROM for Sun Remarketing SCSI card to boot off SCSI drive from the "Startup From" menu

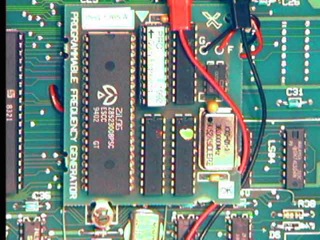

- Programmable Frequency Generator (PFG) - part of MacWorks Plus II

Public Domain

- LRamBo - Modification to Apple 512K Memory Board to provide 2 MB

- 4MB Mod - Modification to CPU board and Memory Boards to provide 4 MB (MacWorks variants only) http://www.freeinfosociety.com/electronics/schemview.php?id=1421

Unknown manufacturer

- ROM switcher - provides dual ROM sockets to allow switching between version H and 3A ROMs with the flip of a switch

Unconfirmed Products

Priam/Tecmar

- Priam interface card and DataTower (containing 86 MB Hard Drive and 60 MB 1/4" Tape Drive, for use with LOS and Xenix)

- The DataTower is reported to be 7" wide X 26" tall X 20" deep, weighing 80 pounds.

- Mentioned in Semaphore Signal and shown on some price lists of the time, but there is no confirmation that these achieved production status

(Comment on this answer)

3.3.1. What does the Lisa's Hardware consist of?

Almost all of the hardware inside the Lisa is easily user replaceable (the CRT + video card are the exceptions). It is also one of the first machines to support software controlled power on/off and floppy ejection. The Lisa is self contained except for a detached keyboard and mouse, with optional external peripherals (modems, external drives, printers.)There are four common off-the-shelf Lisa configurations that were available from Apple dealers:

- Lisa 1 - two Twiggy drives

- Lisa 2 - single 400K 3.5" floppy drive

- Lisa 2/10 - single 400K 3.5" floppy drive, and internal 10 MB Widget hard drive and 1.8A power supply

- Macintosh XL - Same as the Lisa 2/10, with an optional screen modification kit for square pixels.

One or more external 5 MB or 10 MB ProFiles could also be added to any of the above.

Most Lisa configurations are unusable without a hard disk, so Lisa 1 and Lisa 2 units were typically sold with an external 5 MB ProFile (hence the Lisa 2 with ProFile is also known as a Lisa 2/5).

When MacWorks XL was introduced, it became possible to use a Lisa or Mac XL without a hard disk, so some units were sold without the ProFile.

Other combinations are possible since upgrades from Lisa1 to Lisa2's were offered as well as upgrades from Lisa2's to Mac XL's.

When Apple stopped selling the Lisa, much of the excess inventory was sold by Sun Remarketing in various configurations.

Due to the ambiguity about what a particular name represents (for example, a Macintosh XL may or may not have the internal 10 MB Widget depending on local conventions), some documents refer to an X/Lisa to indicate any of the above.

The Lisa family included the following hardware:

- Display

- 12" CRT black and white, crisp one bit display

- 720x364 or 608x432 (with square pixel screen modification kit ie. version 3A ROMS)

- 60 Hz Vertical Refresh

- Software controlled 64 levels of contrast (whole screen) - used as screen saver

- removable nylon anti-glare mesh screen

- external RCA video jack (duplicates the screen using a non-standard composite output signal)

- CPU Board

- M68000 CPU running at 5MHz

- Clean, orthogonal opcode set with access sizes for byte, word, and longs (8,16,32 bit values)

- 8 32 bit data registers

- 8 32 bit address registers

- 16 bit external data path

- 7 IRQ's

- User/Supervisor protected model

- 16 KB ROM with self-test and bootstrap routines

- Custom MMU built from discrete logic and RAM

- Support for 4 contexts for easy process switching, each up to 128 variable sized segments (512bytes-128K)

- Support for memory and stack use, and read only access segments

- RAM

- Two slots support Lisa specific memory boards with parity error detection (and optional soft-error correction, never implemented)

- Architecture supports up to 2MB of directly accessible physical memory

- It's possible to modify the CPU and memory boards to support up to 4MB, but this will work only with MacWorks

- Available memory boards

- Apple 512K (modifiable to 2MB)

- AST RamStak configurable for 512K, 1MB, 1.5MB, or 2MB

- Sun Remarketing configurable for 512K, 1MB, 1.5MB, or 2MB

- I/O Board

- Socket for optional math coprocessor AM9512 or WD2001 depending on I/O board version - never used

- Zilog 8530 Serial Communications Controller

- Two serial ports (RS232C 25 pin with optional hardware handshaking)

- Support for Async, BiSync, SDLC, HDLC

- Half/Full duplex, 38.4Kbps max under most conditions, except for AppleTalk (224Kbps) and 57.6 Kbps with MacWorks Plus II

- Parallel Port

- Provides connection to external ProFile hard drive, or a printer (ADMP, Daisy Wheel, Canon InkJet), but mostly used for hard drives. Not available on Lisa 2/10's as this connector is routed internally to the internal 10 MB Widget hard drive instead.

- Managed by VIA2 (6522 Versatile Interface Adapter)

- Sound

- One channel PWM square wave with volume control implemented by shift register and timer on VIA1 (Similar to the sound produced by Commodore Pet's, but much louder and with software controlled volume.)

- Used for beeps and clicks

- COP421 Microcontroller (Control Oriented Processor)

- Software Power On/Off and Alarm clock

- Real time clock (limited to 16 year range, base year controlled by the operating system)

- Keyboard and Mouse interface

- Keyboard

- 3 pin 1/4" Phone plug and coiled cord.

- shortcut pages pull-out under keyboard inside a special tray (Lisa1)

- multilingual accents

- n-key roll over with numeric pad

- auto-detection of keyboard language changes ROM messages

- Mouse

- Single button mechanical-optical mouse attached by a DE9 connector (also compatible with Mac 128, Mac 512, Mac 512KE and Mac Plus. Note that the mouse shipped with Lisas is physically different in appearance from these.)

- The Lisa Power Supply may be one of two versions, each with a North American and International variant

- Lisa 1/2 (original Apple version)

- North American variant rated 1.2 Amp at 120V 60 Hz

- International variant rated 0.7A at 220-240V~ 50 Hz

- Lisa 2/10 Mac XL "DataPower" version with increased capacity to support interal Widget 10MB hard drive

- North American variant rated 1.8 Amp at 120V 60 Hz

- International variant rated 1A at 220-240V~ 50 Hz

- The later, higher rated version is regarded as more durable, and can be switched between 120 and 220V operation via internal jumpers.

- Storage

- Floppy Media controlled by a dedicated 6504 CPU. The 2/10 uses an Integrated Woz Machine chip, the Lisa 1/2 uses a discrete component state-machine version of the Woz Machine.

- Dual 860K 5.25" Twiggy drives in Lisa 1 or

- Single 400K 3.5" SS/DD Sony floppy drive with software controlled eject, GCR multi-speed encoding

- Single 800K 3.5" DS/DD floppy drive (same as above but double sided) aftermarket upgrade available for use with MacWorks Plus/II

- Apple Hard Drive Storage

- External 5MB or 10MB ProFile hard drive with a Z8 CPU and error sparing

- Internal 10MB Widget drive in Lisa 2/10

- Third Party Hard Drive Storage

- Sun20 - 20MB parallel port drive installed internally in lieu of Widget. Also available in 30 and 40 MB.

- X/ProFile and IDEfile - modern replacements for ProFile drives using IDE drives or flash memory

- Priam card for use with Priam DataTower (86MB hard drive and 60 MB tape drive)

- SCSI card (for use with MacWorks Plus/ II)

- Three Lisa proprietary expansion slots. Known expansion cards:

- 2 Port Parallel Port Card - (common) for additional ProFile(s) or ADMP (Apple Dot Matrix Printer similar to ImageWriter)

- 3 Port Parallel Port Card - (very rare) similar to 2 port card

- 4 Port Serial Card - (rare) only usable with Xenix due to lack of drivers

- AppleNet Cards (very rare) - not released as a commercial product

- Test Cards (very rare) - used for manufacturing (only known cards that implement DMA transfers)

- SCSI Interface - (common) some have hard drives mounted on the card. Only used by MacWorks Plus/II

- Priam Card - (very rare) interface to Priam DataTower (86M hard drive and Archive Tape drive)

- LisaDAC Sound Card - (rare) - only used with MacWorks Plus to provide similar sound capabilities as a Mac Plus

- X/Lisa SCSI Accessories Card - (rare) aka LSAC, allows booting MacWorks Plus/II from a SCSI drive

- Other third party upgrades

- XLerator (12.5, 16 or 18 MHz 68000 with on-board zero wait state RAM, options: SCSI port and MC68881/2 FPU) performance upgrade for use with MacWorks XL 3.0 - MacWorks Plus II

- ROM switcher (facilitated installation of two sets of ROMs for quick configuration change between Lisa and MacXL)

(Comment on this answer)

3.3.2. What kind of Lisa do I have?

Lisa 1

Lisa 1's have two Apple designed and manufactured 5.25" double sided 860KB floppy drives called Twiggies. The Lisa 1 is very rare because most of them were upgraded to Lisa 2's, since the Twiggy drives were unreliable.

Lisa 2

The Lisa 2 has a single 3.5" floppy drive (where the lower Twiggy drive used to exist), these come in two primary flavors - the Original Lisa 2, and the Lisa 2/10.Common features:

The stock Lisa 2 has a single sided (400K) Sony floppy drive.

A third-party upgrade provided a double sided (800K) floppy drive (Sony or Chinon) instead. These 800K drives are only supported by MacWorks Plus, MacWorks Plus II, and in MacWorks XL 3.0 using the HFS-AL software package.

Original Lisa 2

The Lisa 2 has a parallel port on the rear beside the mouse connector, it does not have an interrupt switch.

- A Lisa 2 with a 5MB external ProFile drive is often called a 2/5.

- Although a stock Lisa 2 does not have an internal hard drive, a third-party hard drive may be installed internally.

Lisa 2/10

The motherboard and I/O boards for these are different for the Lisa 2/10. The motherboard does not have an external parallel port beside the mouse connector (it is routed internally to the drive cage). It does have an interrupt switch beside the Serial B connector. The I/O board shows up as ROM version 88 and has a single chip Integrated Wozniak Machine (IWM) chip. It lacks the NiCAD battery pack.- A stock Lisa 2/10 has an internal 10MB Widget hard drive, which sits where the upper Twiggy drive sat on a Lisa 1.

Macintosh XL

The term "Macintosh XL" is ambiguous. Depending on local convention, it may mean:- Lisa 2 that has the screen modification kit that provides square pixels (like the Macintosh) instead of the 2:3 tall rectangular ones characteristic of the Lisa.

- Lisa 2 running one of the MacWorks variants, regardless of the screen configuration.

- Lisa 2/10 running one of the MacWorks variants.

(Comment on this answer)

3.4.1. How do I clean my Lisa's yellowed case?

Take the Lisa apart, remove all of the external case panels off the steel frame. DO NOT LEAVE ANY METAL PARTS, ONLY WASH THE PLASTIC! Run them through the 'Pots and Pans' cycle in your dishwasher with a double shot of detergent.This will clean all the dirt and fingerprints off and remove a lot of the yellowing that comes from many years of absorbing the atmosphere.

(The author used Sun Light Gel by Lever Brothers, but other detergents may work.)

There have been some discussions on some of the other LEM lists, like the Compact Mac list, that mention cleaning some very smoke yellowed compact case with detergent and bleach and leaving them out in the sun. (Careful, this could damage the plastic.)

Source: Dan Pennington, Brooklyn Park, MN / LisaList 2003.09.23

�(Comment on this answer)

3.4.2. How do I take apart the Lisa?

Front Cover

- Below the front cover are two thumb-sized detents. Press up on these to disengage the plastic latches, and you can swing out the bottom of the front cover. The top of the front cover will then come free.

Rear Cover

- At the top of the rear cover are two thumb-screws. Loosen these a few turns to disengage the latches (the screws are captive so should not be removed completely... stop turning when you feel increased resistance). If it is hard to turn the screws, or the latches do not disengage, you may need to press-in the rear panel beside each screw while turning.

- Once the latches are disengaged, tilt out the top of the rear panel and lift.

Re-assembly notes:

- fully loosen the thumbscrews (counterclockwise)

- ensure the inner latches on the thumbscrews are horizontal before closing the panel

- check the slots in the chassis that receive the bottom of the back panel are not obscured by the card cage (if so, the card cage is not fully inserted)

Card Cage

Card cage removal/installation is best done while facing the rear of the Lisa.

- Remove the rear cover.

- Just behind the connector panel, there is a horizontal bar. Grab this bar at each end with your fingers, place your thumbs on the chassis below the connector panel, and pull with your fingers while pressing with your thumbs.

Notes*

- The card cage must be installed square with the chassis (if inserted on an angle, it will be very hard to install, and a connector might be cracked or broken)

- To fully seat the internal card cage connectors, you may need to put substantial pressure on the bottom edge of the card cage

- The connectors will insert much more easily and smoothly if cleaned with an "electronic contact cleaner" that contains a silicone lubricant (do not lubricate with anything else)

- Place your left thumb on the card cage connector panel below expansion slot 1

- Place your right thumb on the card cage connector panel, just beside the power supply

- Press evenly with your thumbs until the slots in the chassis are visible below the connector panel

- If the connectors are very tight, wiggle the card cage slightly from left to right while applying pressure

CPU Board, I/O Board, Memory Board

- Remove the Card Cage.

- Simultaneously lift up the two ejectors at the ends of the top of the applicable board, then slide the board out vertically.

Re-installation notes:

- Arrange the ejectors vertically before re-inserting a board

- Match the coloured ejector (red, yellow, blue) to the notation on the card cage

- The connectors will insert much more easily and smoothly if cleaned with an "electronic contact cleaner" that contains a silicone lubricant (do not lubricate with anything else)

Power Supply Unit (PSU)

- Remove the rear cover.

- Unscrew the thumb-screw at the bottom of the PSU until it is loose vertically. This screw is captive, so do not remove it. It is spring loaded, so when it comes free, it will pop up slightly. If the screw is very tight, try pressing in on the power supply; if all else fails, use a flat blade screwdriver to loosen the screw.

- Grab the turned-up plate at the bottom of the PSU with your fingers, place your thumb on the chassis below the PSU, and pull with your fingers while pressing with your thumb.

Drive Cage

- Remove the front cover.

- Unscrew the thumb-screw at the bottom-front of the drive cage until it is loose. This screw is captive, so do not remove it. It is spring loaded, so when it comes free, it will pop out slightly. If the screw is very tight, try pressing in on the drive cage; if all else fails, use a flat blade screwdriver to loosen the screw.

- Slide the cage out slowly, disconnecting the cables as they become accessible. If there is an internal hard disk, be careful to avoid jarring or bumping the drive cage.

Re-installation notes:

- When sliding the cage in, be careful to dress the cables so they are not pinched between the cage and the chassis

- If the cage is not inserted all the way, the front cover may not close properly

Expansion Slot Card

- Remove the rear cover. The card cage does not need to be removed to remove/install expansion slot cards.

- Pull out the metal hook at the end of the applicable slot about 1 inch (2.5 cm).

- Rotate the hook 90 degrees clockwise to open the ZIF connector.

- Slide the expansion card out, disconnecting internal cables as they become accessible.

- Rotate the hook 90 degrees counter-clockwise to return it to the vertical position, and slide it back in.

Top Cover

![]()

Danger: Removing the top cover will expose the high voltage and implosion hazards of the CRT. Proceed at your own risk*

When working around a Lisa with top cover removed, take suitable precautions including:

- notify someone nearby that they may need to summon medical assistance in case of an accident

- wear eye and face protection to protect from flying glass in case of implosion of the vacuum tube

- ensure the high voltage circuit is discharged (disconnect the power and leave untouched for 24 hours)

- do not become a conductor (wear insulated shoes, work with one hand only, avoid touching the chassis with your other hand, arm, etc.)

- Remove the front cover and the card cage.

- At the rear of the top cover, there are two screws inserted from below. They are accessible from the card cage area via round holes punched in the chassis. After removing these screws, lift the rear of the top cover and unhook it from the front of the chassis.

Video Board

![]()

Danger: See the warnings regarding the top cover*

During this procedure, be very careful to not apply stress to the CRT. The neck is fragile and easily broken, causing an implosion and flying glass

- Remove the top cover.

- Remove the box covering the rear end of the CRT. Be careful to avoid stress on the CRT socket via the short white ground wire connected to this cover.

- Disconnect the multiwire socket from the end of the CRT.

- Disconnect the two-wire horizontal and vertical deflection cables from the video board.

- Disconnect the multi-wire flyback transformer cable from the video board.

- Remove the two screws from near the top of the video board.

- Tilt the board forward slightly and pull up to remove from the card-edge connector at the bottom.

�

(Comment on this answer)

3.5.1.1. Lisa Office System Won't see my Two Port Parallel Card in some slots (error 10737), what can I do?

This is a normal characteristic of the Lisa OS, which is not "plug-and-play". The Lisa OS does not automatically recognize hardware changes such as adding more drives (even though the ROM is happy to try to boot from a newly installed card).In the default LOS installation, only slot 2 is configured in the preferences to contain a dual parallel card, and only the lower port of slot 2 is configured to have a ProFile connected.

The resolution is to temporarily connect your drive to the lower port of slot 2 (or to the built-in port), boot LOS from that drive, and edit the LOS "preferences" to specify that a dual parallel card and ProFile are attached to the desired slot and port. Then you can shut down, move the card and/or drive, and start up from it.

Source: James MacPhail / LisaList 2006.05.26

�(Comment on this answer)

3.5.2.1. What are the characteristics of the Dual Parallel Port Card?

The dual parallel port card is the most common Lisa expansion card.It provides two external DB25 parallel ports.

For those Lisa operating environments that include appropriate drivers, each port can be used for a parallel port printer (eg. the Apple DMP), or a parallel port hard disk (ProFile or equivalent).

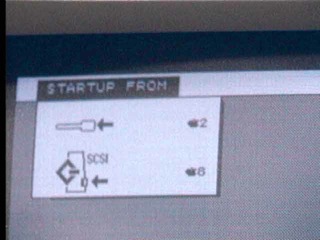

The additional parallel ports appear in the "Startup From" menu, so attached hard disks can be bootable (although some operating environments do not boot properly from an expansion card port).

The dual parallel port card was manufactured by Apple Computer.

Two ROM revisions exist, with a minor difference between them. As most operating environments use their own ProFile driver code, the difference appears to be insignificant.

Using a dual parallel port card with MacWorks Plus and MacWorks Plus II

The Macintosh driver numbers for AppleTalk (DRVR FFD6) and the AppleShare client software (DRVR FFD7) are the same as the driver numbers assigned to ProFiles that are connected to some expansion slot ports.

- In MacWorks Plus, this can interfere with ProFiles connected to slot 2 lower and slot 1 upper

- In MacWorks Plus II, this can interfere with ProFiles connected to slot 3 lower and slot 3 upper

Therefore, for best results in these environments, when using dual parallel cards with ProFiles:

- turn off AppleTalk, or

- if using MW+II, use slots 1 and 2, or

- if using MW+, use slot 3, slot 2 upper and slot 1 lower

MacWorks Plus II 2.0 and up were designed to boot properly from any parallel port, however some problems may occur when trying to boot MacWorks Plus 1.1h and earlier from an expansion slot parallel port.

Using a dual parallel port card with Lisa Office System

Boot from the built-in parallel port and adjust the preferences to identify which expansion slots and ports have ProFiles attached to them.

Using a dual parallel port card with Lisa Xenix

When installing Xenix, you are offered the choice of configuring the &/usr partition on a second drive. You may use this info to configure additional drives:

Devices and typical mount points are assigned as follows:

Slot 1 lower: pf2 /usr Slot 1 upper: pf3 Slot 2 lower: pf4 /u Slot 2 upper: pf5 /vExample, to connected a 5 MB ProFile to the lower port of a Dual Parallel Card in slot 2

- Boot Xenix into maintenance mode, and:

mkdev pf4 mount /dev/pf4 /u mkfs -y /dev/pf4 9728 1 64 mkdir /u/lost+found

- Note that 9728 = $2600, which is the number of sectors on a 5MB ProFile; use 19456 = $4C00 for a 10MB ProFile.

(Comment on this answer)

3.5.3.1. What are the characteristics of the 4 port serial card?

The 4 port serial card includes two DB25 connectors on the card, and two headers for ribbon cables that go to a back panel plate to provide two additional DB25 connectors.Drivers for this card are included only in Lisa Xenix, no other operating systems support this card.

This card does not include a ROM, and does not show up in the "Startup From" menu.

This card was made by Tecmar.

Using the 4 port serial card with Xenix 3.0

Install Tecmar card in slot 3, JPR set to X4, SW1 all on.

Boot Xenix into maintenance mode and type:

- /dev/mkdev tecmar

- /dev/tty20 through

- /dev/tty23 using the correct driver (#10 instead of #5 for the 2 serial tty0a and tty0b).

- Manually edit (with vi) /etc/ttys to include 12tty20 through 12tty23

- Shutdown (use the shutdown command to fsck the drives)

- Restart and command-d to enter normal mode (serial ports don't work in maintenance mode)

Connect terminal(s) to Tecmar card, 9600 baud.

tty20 = P2 (DB25 lower) tty21 = P1 (DB25 upper) tty22 = P4 (header lower) tty23 = P3 (header upper)Thanks to Guido Deiana for his assistance in getting this working! �

(Comment on this answer)

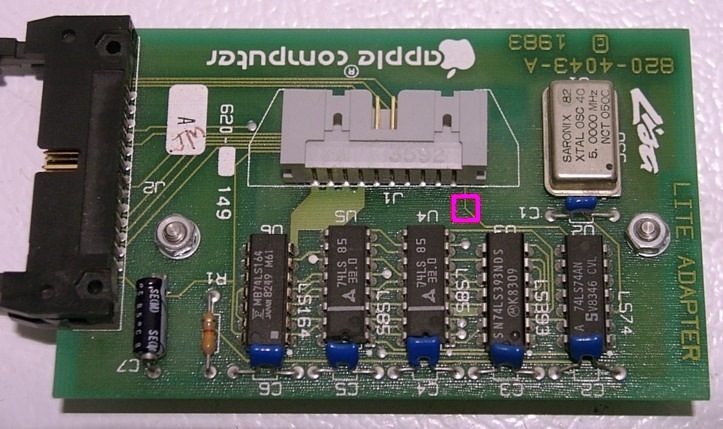

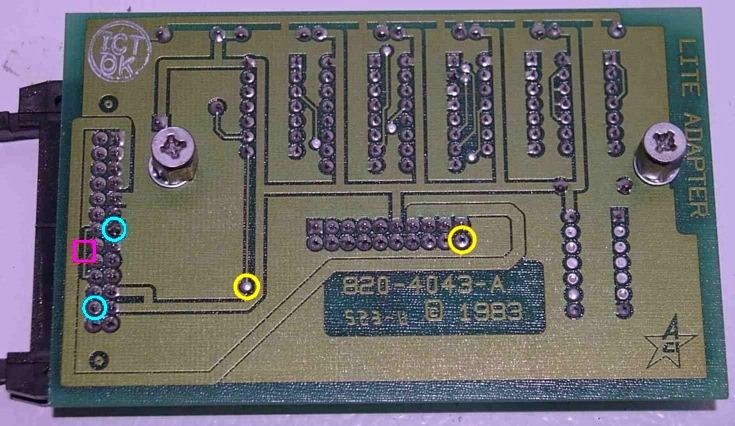

3.5.4.1. What SCSI devices work with the Lisa?

Two SCSI interfaces were developed for the Lisa running MacWorks Plus or MacWorks Plus II. SCSI drivers are not available for the Lisa Office System, Workshop, Xenix, or other environments.

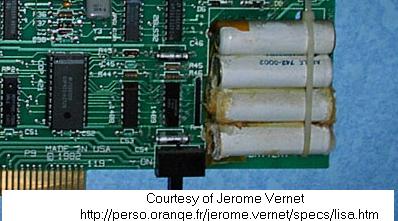

1. The Sun Remarketing SCSI expansion card provides an internal 50 pin connector and a DB25 external connector like the Macintosh Plus. These cards have soldered-in terminator resistors which may need to be removed for reliable operation of some internal+external device configurations. Some of these cards were sold with a hard-drive installed on the card.

- The QuickBoot upgrade enables booting MacWorks Plus/II directly from a SCSI drive

The Sun Remarketing SCSI card.

Startup from the SCSI card.

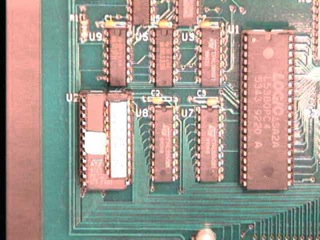

The QuickBoot ROM and PAL chip which allows for booting.

2. The original XLerator has an optional SCSI port. A cable provides a rear panel DB25 connector. Since this port is accessible at the full speed of the 16 MHz CPU, it is sometimes substantially faster than the expansion card SCSI port, depending on the drivers in use.

- The X/Lisa SCSI Accessories card provides additional features for use with the XLerator SCSI port

- internal 50 pin SCSI, 4 pin power and 2 pin fan connectors

- ROM to boot MacWorks Plus/II from a SCSI drive (subsequently available as QuickBoot for the Sun SCSI card)

- Some of these cards were sold with a hard-drive installed on the card.

In general, those SCSI devices that work with the Macintosh Plus will also work with a Lisa SCSI port running MacWorks Plus/II.

Potential Problems

- If an XLerator is installed, hard drives may not work with "blind" read/writes due to the increased speed (just as with a Mac Plus with an accelerator installed)

- Some later SCSI drivers require more space in the System Heap than is available in a machine with 2MB of RAM. Using 4 MB or switching to an older driver can alleviate this problem.

Specific unusual devices known to work:

- ScuzzyGraph (provides 8 colour display with extended desktop)

- Asante Mini EN/SC (ethernet adapter)

- Faralon EtherMac Microscsi (ethernet adapter)

- Dayna Port SCSI/Link-T (ethernet adapter)

Specific devices known to NOT work (although success may be possible with a particular driver version):

- GCC PLP II SCSI Laser Printer

- this printer relies on precise timing to scan properly

- PLI SuperFloppy aka TurboFloppy

- This 1.4MB HD floppy drive with SCSI interface includes a driver in its ROM. The driver uses a 68K TAS instruction, which is the only instruction that generates a read-modify-write cycle. The Lisa memory boards cannot perform this kind of cycle, so a crash or hang results. This drive does work if an XLerator is installed and turned on, as the XLerator RAM does support this kind of cycle.

Faralon EtherMac Microscsi Ethernet Adapter.

Dayna SCSI Port.

Note: The images on this page provided by http://lisa2.com , used with permission

�(Comment on this answer)

3.6.1. The floppy drive refuses to eject, or I can't insert a floppy in it. How do I repair it?

The likely cause is that there is some old dried up grease in the joints which prevent the ejection mechanism from functioning properly. This is a very common problem with the 400K Sony drives.Remove the Lisa's front case. Unscrew the drive cage nut. Carefully pull out the drive cage. There are cables that you can either leave hanging if you have a work surface nearby, or if you do not, you should unplug and remember the polarity of.

On my Lisa, the cable that comes from the motherboard and plugs into the LisaLite floppy adapter on the left hand side of the drive cage is not keyed. If yours is also not keyed, and you put this cable in backward later on, you'll short out the power supply and prevent the Lisa from powering on.

The floppy drive sits on four raiser posts. Unscrew these from the drive cage to remove it.

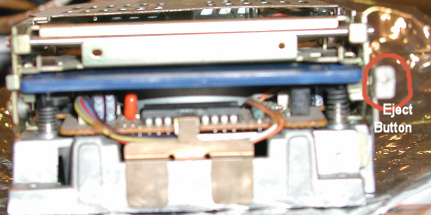

If there's a trapped floppy disk, press the eject button which is located to the right hand side of the drive.

Next, you'll need a junk floppy that you don't care about (one whose door is still functional and won't break inside your drive, or one that no longer has a door and spring), some WD40, paper towels, cotton swabs, and a tube of white lithium grease which you can find at hardware stores or some auto stores.

You should take the floppy outside, or at least in a well ventilated place (away from open flames of course) where you can safely spray the WD40 without getting it on furniture, etc.

Be careful to spray the WD40 at an angle, away from the center of the drive where the read/write head lives. WD40 on the R/W head is not a good idea. You're not trying to lubricate the drive, instead, you're using the WD40 to dissolve the old grease.

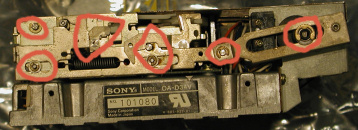

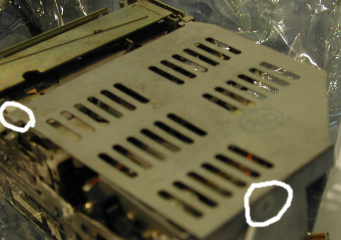

Insert the junk floppy and eject it repeatedly as you use paper towels and a few cotton swabs to wipe away the WD40 and old grease out of the joints. Next, apply a small amount of the lithium grease on a clean paper towel, and use a clean cotton swab to apply a small amount of the lithium grease on the joints circled in red. As before, insert and eject the junk floppy several times. As you do so, spread the lithium grease in exposed the areas of the joints.

When you're done, discard the cotton swabs, the junk floppy, and paper towels.

- If you have a floppy cleaning kit, then insert the drive back into your Lisa, reconnecting all the cables.

Get a floppy drive cleaning kit and clean the drive head. The easy way to do this is to power off any hard drive, and repeatedly attempt to boot from the floppy. This will spin the head cleaning floppy and clean the drive.

- If you don't have a floppy cleaning kit, unscrew the small round black screw on the back of the floppy drive. The cover hooks into the sides at the edges. Note how it fits in before you remove the cover.

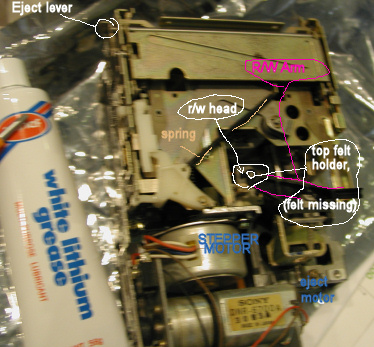

Remove the cover, exposing the drive read/write head.

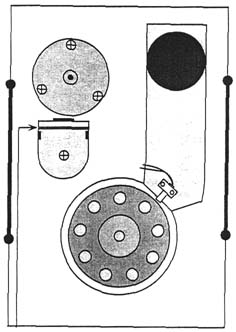

On a normal 400K floppy drive, the black plastic arm above the head has a small circular piece of felt (which applies pressure to the top side of the media, holding it against the head on the lower side). (As shown in some of the pictures, on my drive the bit of felt fell out a long time ago. However, some drives don't work properly if this pressure pad is missing.) This top part isn't part of the read/write head. The read/write head is underneath this. With a double sided 800KB drive, there are two read write heads (one on top, one on the bottom.)

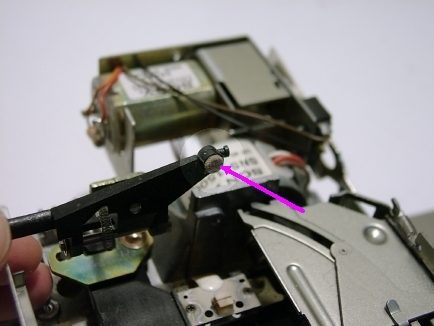

The above image better illustrates the top half of the drive arm being flexed upwards and shows the felt pressure pad. If yours is missing the felt pad, you'll need to fashion a replacement. (One person has made one out cotton swab tips, though this is not ideal.)

Using another clean cotton swab and isopropol alcohol, gently wipe the r/w head. You must be very gentle to avoid damaging the thin flexible metal head mount. Repeat cleaning the r/w head with a new clean cotton swab until you see no residue on it. Put the cover back on, replace the screw, then insert the drive into the drive cage, and into the Lisa, reconnecting all the cables.

Next replace the Lisa's face plate and power the Lisa back on.

If you didn't use a head cleaning kit, insert a blank disk and attempt to boot from it. The Lisa should eject this with an error.

Insert a boot disk, such as the one for MacWorks, and attempt to boot from it. This should work.

Sources: SunRem Do It yourself guide, James MacPhail - suggestion for using white lithium grease.

�(Comment on this answer)

3.7.1. How do I low level format my ProFile hard drive?

When installing an operating environment, such as the Lisa Office System or one of the MacWorks variants, all of the sectors of a ProFile/Widget hard disk are written with zeros before the actual file system structures are written to the disk.If this initialization fails consistently, it is possible that the drive is damaged and needs low-level formatting and/or further repair.

A low-level format is different from the normal initialization that installing an operating system on a ProFile or Widget does. During low level formatting, extra synchronization markers and track/sector ID's are written on the tracks in between the sector gaps to help the hard drive find the sector/track it's seeking.

In normal operation, this extra data is never written to. Over time, the strength of the magnetic signal of this data can fade, or is physically damaged as vibrations cause the r/w heads to smash into the platter.

When this happens, you get data errors. In cases where the damage is limited to only a few sectors, the hard drive can relocate a damaged sector to one of the spare sectors. ProFile drives have up to 32 spare sectors. Once they run out, any more damage results in symptoms such as loss of data and instability to the OS.

Should the first track be damaged, the OS will not be able to install and use the drive.

If using the OS installer to re-initialize/format the drive fails, the first level of service to address these issues is to do a low-level format. Unfortunately, in order to do this, you'll need an Apple /// computer with a ProFile interface card, the special low-level format ROM for the ProFile's Z8 processor, and the Apple /// ProFile formatting software to issue the commands. ProFile hard drives configured for normal operation do not have the firmware necessary to do low-level formats.

The technique, hardware, and software required to perform a low-level format of a Widget hard drive is unknown.

Low-level formatting cannot cure all problems, as damage to the disk surface or electronic failures may require replacement of some components. In short, for most of us, low-level formatting is just not possible. You're better off buying a replacement hard drive.

If someone out there has the right hardware to perform low-level formatting, please let us know if you'd be willing to perform this valuable service for the Lisa community.

�

(Comment on this answer)

3.7.2.1. At startup Lisa shows a hard drive error 81, what can I do?

This information is applicable to a Lisa 2/10 or Macintosh XL containing a 10MB internal Widget hard drive.

- error 81 is not exclusively caused by misadjustment/failure of the Widget brake, other problems can generate this error too, such as a bad cable/connection.

When the Lisa is turned on, the Widget drive will spin up and perform its own self-test. This happens independently of, and concurrently with, the Lisa's self-test. The Widget self-test and brake-release described below does not recur if the reset button is pressed; it occurs once at power-on only.

After the Widget spins up, the electric head brake releases with a distinct clunk or clack followed by the characteristic squeaking noise of the Widget head motor.

If the brake does not release, the Widget's self test won't complete successfully and the drive does not respond to the Lisa; the result is a cross over the internal drive icon with error code 81.

Without further information, many people assume that they need a whole new hard drive. Rather than spend the money, they shelve the computer. Well, it's time to dust it off! Error code 81 may simply mean the brake is out of adjustment. You can fix it, easily, in under an hour, with a #1 Phillips- head screwdriver and a .012 inch (0.3 mm) feeler gauge. Here's the complete procedure:

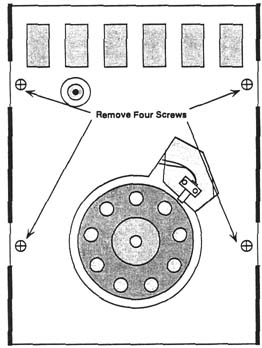

1. Disconnect the computer's power cord from the wall outlet. 2. Remove the disk-drive cage as shown in Figures 1 to 3. 3. Disconnect all data and power cables from the installed drives. 4. Turn the cage upside down. This puts the relatively light disk drive on top and the relatively heavy hard drive on the bottom.

Figure 25 Four screws hold the Widget assembly to the sheet metal support bracket.

5. Use a #1 Phillips-head screwdriver to remove six screws (three on each side of the cage) which hold the hard drive in place. 6. Lift the drive cage straight up. This leaves the hard drive upside down on the table. 7. Use a #2 Phillips-head screwdriver to remove four screws from the sheet metal support bracket as shown in Figure 25. Lift the bracket away and put it aside. 8. Locate the solenoid marked "Inertia Dynamics, Collinsville, CT USA." Insert a 0.012-inch feeler gauge as shown in Figure 26.

Tighten the screw, reverse steps 7 through 1, and everything should be OK. If not, repeat steps 1 through 9, allowing a little more or a little less clearance, until you get the brake working.

Figure 26 Adjust the brake gap (indicated by the arrow) with a 0.012-inch feeler gauge.

Actual photos of the drive mechanism (courtesy of JDM)

Closeup.

9. At the time of failure, clearance might be as much as 0.075 inch. Loosen the solenoid holding screw and adjust for 0.012-inch clearance.

Source: http://www.cs.dartmouth.edu/~woz/lisatech/page28_29.html ( Lisa/Macintosh XL Do-it-yourself Guide published by Sun Remarketing, Inc. )

Addendum JDM 2006-06-24

- In some cases, the Widget's brake does not release because the drive does not spin up. You may be able to get the drive to spin up by flipping the front side of the flywheel from right to left with the eraser end of a pencil. You have a few seconds after power-on or the Widget's self test will conclude it is not going to spin up to the correct speed and stop trying.

- If you are successful at starting your drive this way, backup your data immediately as it may not start again

Typical Widget self-test timing (seconds)

| 0 | Power-on | Waiting for platter spin-up |

| 10 | Spin-up complete | Waiting for brake release |

| 20 | Brake Release | Start fast surface scan |

| 28 | Fast scan complete | Start slow surface scan |

| 88 | Surface scan complete | Drive Ready |

�

(Comment on this answer)

3.7.2.2. My Profile or Widget drive shows error 84 (or another) on boot. How do I repair it?

An error while trying to startup from a hard drive may indicate a problem with the Lisa, the drive's hardware, or the data on the drive.The troubleshooting suggestions below assume the data on the drive is damaged. However, before assuming the worst, check the following:

- hard drive is properly connected

- hard drive data cable connectors are clean and straight

- Lisa is operating properly (self-test completes with no errors)

- ProFile drives will sometimes fail due to minor corrosion (and thus bad contact) in one or more of the IC sockets on the controller board (inside the ProFile). This can be cured by partially removing and re-installing the socketed chips. Do this one at a time to preserve the locations, and be sure to maintain the correct orientation.

If the Lisa configuration has been changed recently, or it has been out of use for an extended period, also check the power supply voltages at the drive.

If the problem persists, troubleshooting typically uses the following progression:

- attempt to repair the drive using the OS installer

- if repair fails, attempt to re-install the OS

- if OS installation fails, perform a low-level format

- if low-level formatting fails, repair the drive electronics and/or disk assembly

Double initialization for MacWorks

In response to some problems re-installing some early variants of MacWorks, Sun Remarketing had this advice (it may not be applicable to other OS installers):

Source: http://www.cs.dartmouth.edu/~woz/lisatech/page32_33.html ( Lisa/Macintosh XL Do-it-yourself Guide published by Sun Remarketing, Inc. )

Startup error code 84 pertains to Profile and Widget drives. It means the boot blocks are damaged. There are three possible fixes.

Fix one involves double-reformatting the drive-

first under Lisa OS, then under MacWorks XL. Double-reformatting the drive is time-consuming and it only applies to some computers. You can't use this method with a Macintosh XL Screen Modification Kit unless you pull the 3A ROMs and reinstall the old ROMs. Also, double-reformatting doesn't always work.

Editor's Notes: Not sure that this will help anything since it doesn't make sense that one format will make a difference from another. It might help if you are using an old version of MacWorks, which sometimes gets confused if you are installing it over a drive that has existing data. If you have an Apple II or /// available, initializing the drive under ProDOS or SOS may have the same effect as using LOS.Fix two involves reformatting the drive with MacWorks Plus version 1.0. 18 or later. Holding down the Apple and the left Option keys while double clicking the MW Install icon opens the program in the expert mode. Expert mode recognizes most unmountable drives and gives the option to you to reinitialize them. Afterwards, the drive may or not be bootable.

Fix three is low-level formatting.

�(Comment on this answer)

3.7.3.1. What kind of cable should I use between the Lisa and my ProFile drive?

A straight through Male DB25 to Male DB25 cable is needed.Make sure that your cable has all the wires connected to all the pins. (There are DB25 serial cables that look identical, except, they only have a few of the pins wired - DO NOT USE THESE)

If you want to be absolutely sure, get a ohmmeter and check, pin by pin, that pin1 on one end matches pin1 on the other end. Repeat this for all pins and ensure there are no shorts between the pins.

Parallel Port cables and SCSI port cables have been known to work. You can make your own if you are patient.

The requirements are:

- Both ends are DB25 Male

- All pins are wired straight through (that is, pin 1 on one end is connected to pin 1 on the other end. Pin 2 on one end to pin 2 on the other, etc.)

- Pin #7 may need to be removed from one or both ends, as some Apple parallel ports have this pin blocked. If you are making your own cable, it is easiest to remove pin 7 from the connectors before you start assembly.

- The cable should not be very long, 35 inches (90 cm) is the recommended maximum.

You can use flat ribbon cable and crimp-on "IDC" connectors.

The original Apple cable is round with a silver/grey colour, and part number 590-0202-B moulded into the connector hoods.

�(Comment on this answer)

3.7.3.2. Where can I get a replacement ProFile or Widget Hard Drive?

Barring the very rare yard sale, or eBay finds, you're very unlikely to find a ProFile or Widget hard drive, much less one in working order.There are currently two modern replacements for these:

http://sigmasevensystems.com/xprofile The X/ProFile is a commercial replacement for the Lisa and Apple II or ///'s.

http://john.ccac.rwth-aachen.de:8000/patrick/idefile.htm IDE-File is a non-commercial project for Do it yourself'ers.

�(Comment on this answer)

3.7.3.3. My ProFile is very loud, how do I fix it?

The ProFile has no fan, so almost all noises are generated by the disk assembly.Usually the ProFile's "jet-engine" noise can be nearly eliminated by adjusting the static brush.

The static brush touches the bottom end of the spindle axle, and after some period of wear, can vibrate quite loudly.

If you (carefully) remove the hard disk assembly from the ProFile chassis, and remove the circuit board on the bottom, you will see the static brush. A small tweak sideways is usually all that is required to change the point of contact and stop the excessive noise.

Make sure that the brush is still making contact with the axle so that it can do its job, and do NOT "lubricate" the point of contact.

Source: James MacPhail / LisaList 2005.09.07

Larry Pina Recommendations

I've got 4 profiles. Of these 3 make the fridge compressor noise. They've all been alive for over 20 years now and still work. Granted, I rarely turn any of them on, and even then, only for a few hours, but they still work.

The Larry Pina book, Macintosh Hardware Repair Secrets describes how to fix this. It's a bit of a rare book to find, and usually around $30-$40, but it's worth getting. Chapter 13 of this book is what you're after:

"Some hard drives tend to be intermittently noisy, likely an annoying loud refrigerator... The fix is to remove the drive and check for a static discharge button. Intermittent strange noises often mean the discharge piece is too close to the media. Bend it back with a soldering aid as shown in figure 13-29 and the noise will be gone. Be careful when you're doing this... Generally, all you have to do is bend it back a little."(The figure shows a soldering tool (the usual one with a blade on one end and a hook on the other you used to be able to find at Radio Shack) pointing to a circular knob in the middle of the board on the bottom of the hard drive.) It looks a bit like a spiral and is next to a crystal, a chip that has two large resistors under it, and below a large chip with a sticker on it. You can probably use long, a small head flat screwdriver instead.

I've not done this before, nor have I bent back the profile discharge tab - I don't mind the noise since I rarely turn the drives on.

Source: Ray Arachelian / LisaList 2006.05.11

Leave the ProFile powered for 3 days

Letting the hard drive run for three days on its side may heat the grease around the ballbearings and get rid of the noise.Source: Simon Claessen / LisaList 2006.05.12

![]()

NOTE: It's generally not a good idea to run a hard drive upside down, this may cause damage as the drive heads scratch into the surfaces of the platters. NEVER MOVE A HARD DRIVE THAT IS POWERED ON! Power it off first, wait until the platters stop spinning before repositioning it

�(Comment on this answer)

3.7.4.1. How do I replace a Widget Drive?

If you're actually lucky enough to find a spare widget drive and want to replace an old one, or just install a new one, these instructions may help:Tools and Parts: three hands, medium-shafted Philips-head screwdriver, film canisters.

![]()

Before you proceed, make sure that the Lisa is plugged in and that (if the Widget is functional enough) you have booted the Lisa from the hard disk at least once after plugging it in last! The Lisa stores critical system parameters (time/date, device info) in two places: the PRAM and the boot blocks of the boot disk. If the Lisa is unplugged, the parameters in the RAM are lost and must be restored into RAM from the boot disk. Installing a replacement Widget with no parameters in RAM may cause incorrect information to be "restored" into parameter RAM. Incorrect parameter info causes many system problems - be careful!Step 1, Preparation: With the Lisa off, remove the front bezel by pushing up on the two tabs underneath, then pulling out. Loosen the finger screw beneath the floppy drive. Pull the entire drive assembly out of the cavity and rest it upon a clean, anti-static surface.

Step 2, Disconnect: Looking down upon the assembly from the front, remove carefully the three cables connecting the unit to the Lisa: the Widget power cable, the Widget data cable, and the floppy cable. Next, disconnect the two-lead fan cable attached to the top right of the uppermost board. Memorize how the fan wire snakes up around the Widget - you will need to know this later

Step 3, Detach: Gently lay the assembly on one side. Remove the two screws holding the Widget support plate in place in the aluminum rack and optionally place them in film canisters. Carefully turn the assembly over, taking care that the Widget does not shift. Remove the other two screws.

Step 4, Remove: Carefully set the assembly upright with a hand underneath the Widget to prevent it from shifting. Gently spread the aluminum cage, pulling the fan wire away from the Widget in order to avoid a tangle. Lift the Widget up and away from the cage and set it aside.

Step 5, Replace: Pull the fan wire taut and carefully spread the aluminum cage. Lower the new Widget into the proper position, while being careful not to tug or scrape the fan wire. Try to keep the wire from being squashed - remember how it was before you removed the old Widget.

Step 6, Cleanup: Replace the holding screws to secure the Widget in the cage. Reconnect the wires.

Step 7, End: Gently slide the cage back into the Lisa. Be very careful that the cables do not get caught on screws inside the case. Apple mentions this on the TIL, but I can't find it for the life of me! Replace the front bezel and power up the Lisa. If the Widget hasn't been used for a while, it may take a while before it actually starts to work! (or at least this is my experience)

Source: Tom Stepleton / http://web.archive.org/web/19980212223305/galena.tjs.org/~tom/service.html

�(Comment on this answer)

3.7.4.2. What does a working Widget Hard Drive sound like?

See this QuickTime movie of a working Widget startup sequence: http://lisafaq.sunder.net/movies/Widget.movThis view from the bottom of the Widget (while removed from the drive cage) shows the solenoid gap closing as the brake is released around 20 seconds into the sequence.

The squeaking noise during the surface scan is typical of the Widget's head seek motor.

The Lisa's self-test clicks and beeps are also audible. Note that the time it takes for the Lisa to do its self test varies with how much memory is installed (your Lisa self-test may be completed faster or slower).

�(Comment on this answer)

3.8.1. My Lisa has an I/O board that has a four pack of NiCAD AA batteries, what should I do?

You should immediately remove the batteries! If they haven't already leaked, you are very, very lucky. Most of these are very old and the batteries have leaked, usually damaging the board with corrosion!

There is little value to replacing these batteries with new ones, as good ones will only maintain the time for a few hours while the Lisa is unplugged. This is probably why the I/O board used in the Lisa 2/10 does not have backup batteries.

It is perfectly fine to run a Lisa without these batteries, all they do is maintain power to the floppy RAM (which contains the equivalent of the Mac's PRAM) and the real time clock in the COP421. This will be maintained just fine as long as the Lisa is plugged in to power, even though the Lisa is turned off.

That said, the real time clock may be useless as it's range is from 1980 to 1995 (unless you are using an updated version of MacWorks Plus II), and unless you are using your Lisa regularly, you are better off not leaving your Lisa plugged into power where it can be exposed to possible brown outs and power surges. You should also plug your Lisa into a very good power surge protection unit when using it, and leave it unplugged when not in use for an extended period.

More than likely, if you are reading this question, it's already too late and the NiCAD batteries have leaked. You have a few options. You can try to find a replacement I/O board, or attempt to repair your current I/O board.

I found the following web pages pages that address this type of repair. The last link in the list is a failed repair attempt. YMMV.

- http://www.rskey.org/calccorr.htm

- and http://www.flippers.com/images/GamePlan-Corrosion1.jpg

- http://oldcomputers.net/corrosion.html

Instead, try to clean up as much of the damage with an old toothbrush. Be careful not to breathe in any of the dust.

Look at the traces on the board, if any of them are damaged, you'll see a blueish green coating that's different from the board's own lacquer on the solder points, the traces may be raised up or puffed up, or even broken, you should clean the solder points between the traces, then reflow them using a soldering iron. After doing so, use an Ohm-meter, check for continuity.

If the resistance is still high (more than a few Ohms), solder another wire across the solder points of the traces to replace the corroded ones. Be careful not to cause a short circuit.

You may also have to replace any components damaged by the leak, and any damaged by short circuits caused by the leak. In my own case, I had to replace a VIA chip and a COP421 chip because the VIA chip had a bit of melted plastic. I replaced the COP421 chip because the mouse did not work on with this I/O board, but did with another.

COP421 chips are very difficult to find, their only sources are other Lisa I/O boards. According to the Lisa Hardware Guide there are identical COP421 chips inside the Lisa's keyboard, however, no keyboard that I've come across has these. Instead, they are Intel keyboard controller chips. If you have a dead, extra keyboard that has a COP421, you can try to swap the keyboard COP421 with the one on the I/O board. Please let me know if you find such a keyboard. I suspect these were only in the prototypes or very eary keyboards.

If you are able to locate a Mac XL I/O board (does not have an AM9512 socket, has a large IWM chip) and does not have NiCAD batteries or a switch, you can attempt to use this board. However, you'll also need a Lisa XL motherboard, and you should not use the LisaLite floppy adapter with it.

Addendum JDM 2006-06-10

I had suggested that Ray use diluted vinegar to remove the blue stuff on the basis of many well respected postings from a calculator site: http://www.hpmuseum.org.

My reasoning goes like this:

Apparently the leakage from NiCAD batteries is alkaline. A weak acid will help to neutralize this, whereas neutral water will only dilute it. Unless the leakage is neutralized, the corrosion will continue to spread.

The question is then, how does one remove or neutralize any remaining acid? After washing with water, I suggest using a circuit board flux remover, as they are designed for compatibility with circuit boards, and for removing acid residues of some soldering fluxes.